The purpose of the desolventising process is to remove the solvent from the solvent-laden meal, toast the meal to control antinutritional factors, and reduce the moisture and temperature of the meal to levels appropriate for storage and transport.

For meals that have high moisture content such soybean meal, we have developed our VRX™ DT technology which generates a great steam saving in the Meal Drying process.

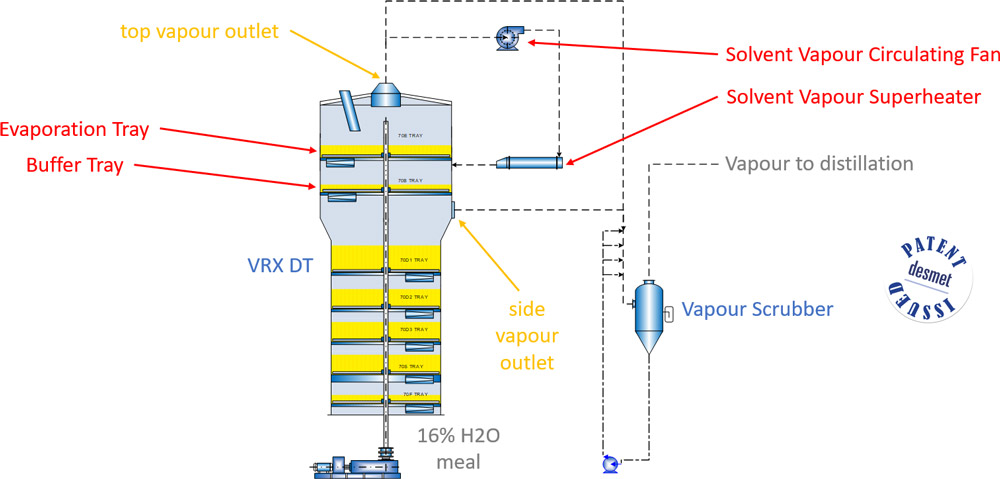

Indeed, our patented VRX™ Desolventizing System utilizing heat from superheated solvent vapour with the purpose of reducing the meal moisture entering to the Meal Dryer-Cooler (DC).

Advantages & Sustainability KPIs

- Very Low Meal Drying Energy: our VRX patented technology uses superheated solvent vapours to initiate the meal desolventising process, resulting in 2-3% lower meal moisture exiting the Desolventiser Toaster and therefore 15-25 kg of steam/ton of seed savings in meal drying section. This results in - 16-20% of steam/ton of seed comparing to conventional DTCT (e.g. DIMAX)

- Reduced DC size, minimizing required air for the Meal Drying process reduced by 25-33% the dust emissions to the atmosphere and reduced by 10-14 % electrical consumption in DC and fans comparing to conventional DTDC (e.g. DIMAX)

- Lower desolventising moisture reduces over-toasting and improves meal quality:

- Meal with less than 200 ppm free hexane

- 80-85% KOH solubility

- 0.02-0.05 delta pH urease activity

- 10% more open area in the desolventising trays allows optimized steam contact rising through meal layers supported above

What is a VRX™ Desolventiser Toaster?

Simplified Flow Diagram

Need more info ?