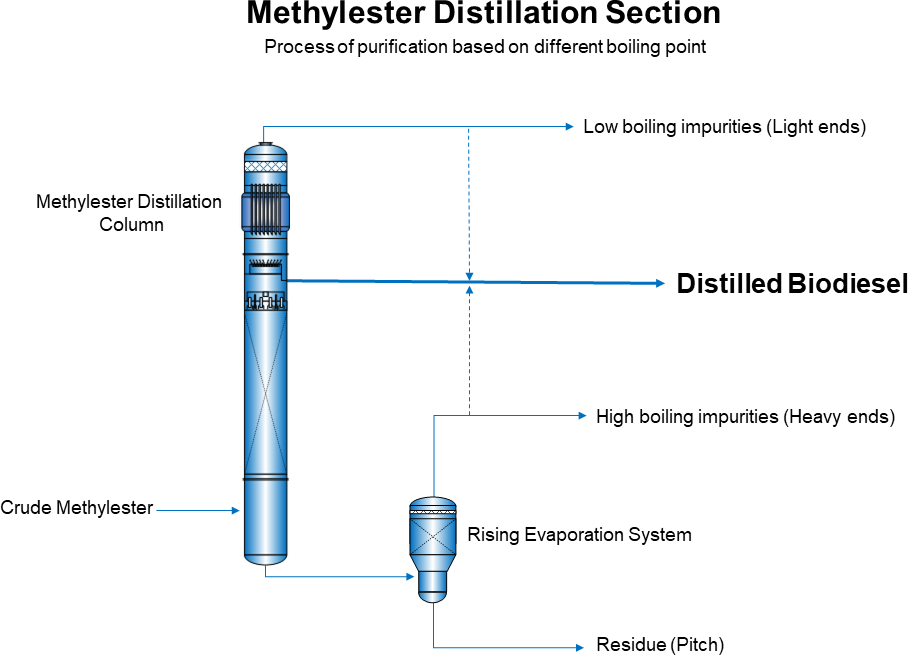

The Methylester Distillation section (or also known as : Methyl Ester Distillation or Biodiesel Distillation) is designed to process crude Methylester to produce the main purified product with a very low content of impurities in order to meet all the international standards for Biodiesel quality.

Other by-products from Methylester Distillation section are the light ends leaving from the top of distillation column. The heavy ends and pitch that can be recovered from the pitch squeezing system available in dual option : Kettle Reboiler or Desmet’s Rising Evaporation System for higher Sulphur content feedstock, lowest Monoglyceride content of distilled Methylester and improved yield.

The light ends and heavy ends can either be sent to storage with a dedicated line or be mixed with the distilled Methylester thanks to our unique rising evaporation system, while the pitches are directly sent to storage to be further utilized.

Desmet advantages in Methylester Distillation section

- Higher Sulphur content feedstock

- Lowest Monoglyceride content

- Improved yield

- Minimum energy consumption that can be achieved by multiple heat recovery equipment and by low pressure steam generation

One of our recently commissioned biodiesel distillations have been placed in Paraguay, Inpasa. Thanks to our continuous R&D and years of industrial experience, our biodiesel distillation purifies crude Methylester to meet the highest quality standard.

For more info on our successful installation on Methylester Distillation Plant, get our complete reference list.